3D-Printable Prosthetic Devices

3D-printable prosthetics are changing the face of medicine, as engineers and physicians are able to develop prosthetics that are fully customized to the wearer. Consumer 3D printing is leading to an even bigger revolution: "DIY" assistive devices that can be printed by virtually anyone, anywhere.

e-NABLE is a network of passionate volunteers using 3D printing to give the World a "Helping Hand." They support the Maker Movement in mechanical hands by bringing together designers, engineers, physicians, 3D print enthusiasts, families and amputees, to create, innovate, re-design and share 3D-printable prosthetics.

Medical science is seeing a significant boost from 3D printing. New startups in the 3D manufacturing realm are creating better prosthetics and customisable medical devices that are worlds more advanced than what came before.

For example two startups – Bioniks and Voodoo Manufacturing – are creating unique prosthetics for patients. Bioniks, a bio-medical printing startup based in Pakistan, has now created a total of 25 bionic arms.

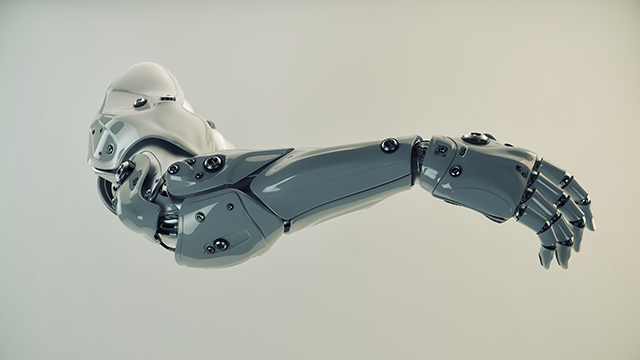

These are advanced prosthetics like those of the Bioniks ‘Robotic Arm’ prosthetic that includes motorised joints as well as custom fitting through 3D printing, says Bharathidasan Moorthi, a digital marketing manager representing the company.

“We are researching on other robotic arms to be printed and tailored to meet specific requirements,” Moorthi adds. “Every arm delivered by Bioniks is different because each of them must be measured on to cater to the nature of disability.”

Bioniks says it’s the first company of this kind in Pakistan and expects to be able to tap into the extensive disabled market catering first for those missing arms before extending into other prosthetics such as dental prosthetics, leg prosthetics and fingers prosthetics.

The company is currently reliant on outside sources of funding – such as crowd campaigns. This is because the cost of creating a 3D customised prosthetic is still about half again more than a traditional prosthetic. Bioniks is cutting its profits for the time being and working on ways to cut costs in order to eventually be self-sustaining, the company says.

The future of 3D-printed prosthetics

The recent ubiquity of 3D printers and innovations in prosthetic design, manufacturing and distribution offer a viable solution for the millions of people living with limb loss around the world. In the United States alone, close to 200,000 amputations are performed each year, yet, with prosthetics priced from $5,000-$50,000, having one can almost be considered a luxury.

Traditionally, the process of getting a prosthetic limb can take anywhere from weeks to months. Because prosthetics are such personal items, each one has to (or should) be custom-made or fit to the needs of the wearer. However, as 3D printers become more affordable, with some available for less than $200, the possibility of anyone being able to design and print a prosthetic limb in their home or local community is rapidly becoming a reality.

With 3D printing, kids can create a prosthetic based on their needs, such as an extendable arm that allows him or her to reach down effortlessly to pick up items off the floor. Akin to printing a document, printing a prosthetic is quickly becoming as easy as pressing “print” and watching the 3D printer build layer upon layer.

In the near future, prosthetics will be seamlessly integrated into people’s everyday lives with minimal effort. New 3D scanning and body modeling technologies from companies such as Body Labsenable people to 3D scan their limbs and have prosthetics modeled after them, making for more natural fitting and appearance.